- Value Chain Excellence

- Company Business Performance

- Supply Chain Performance

- Supply Chain Strategy

- Integrated business management (S&OP)

- Digital Transformation

- Operational Improvement

- Transparency

- Complexity

- Agility

- Responsiveness

- Customer Needs

- Delivery Reliability

- SC Segmentation

- Inventory optimization

- Throughput Times

- Order Management

- Planning Excellence

- Cost management

- Logistics Cost

- Working Capital Optimization

- Supplier Optimization

- Transport Optimization

- Network Optimization

- Post Merger Integration

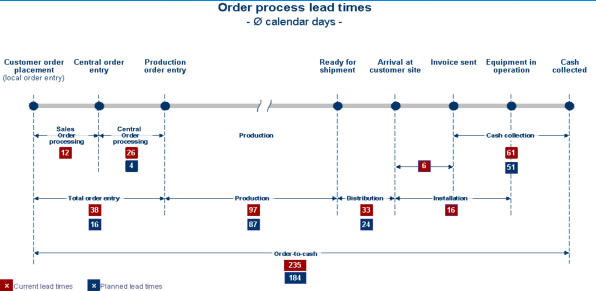

THROUGHPUT TIME MANAGEMENT

Throughput times are linked to synchronization of

flows, and volume considerations for each step

•

In many production environments we find

long order lead times, linked to long

throughput times. Sometimes the time driver

resides in complicated order clarifications, in

other situations it is linked to long waiting times

of intermediate products after each

production step.

•

In any case, when looking with a fresh

perspective on the chain, and asking some

questions on current practices, the first

opportunities for improvement get visible.

•

But - the impediments are in the detail… only

based on a thorough understanding of time

drivers, lot size drivers, and exceptions and

escalations which destroy the planned

sequences, solutions can be identified.

•

Our portfolio of analytics, and even more on

solutions, is very wide in this area. But, as an

easy entry, we focus on two key processes for

an overview, to get a first understanding, and

then select the appropriate detailed

approach for targeted “deep dives” to

identify unnecessary time drivers, and define

solutions for improvement.

•

In most cases, a clever segmentation

approach is a key enabler for significantly

reducing average throughput times. But, of

course, a lot of the other supply chain

performance enablers play a vital role in

accelerating the flow of goods, and the

reduction of throughput times, like planning

excellence, integrated order management, or

creating real-time transparency.

•

Significant throughput time reductions are also

typically driven by integrative operational

improvements, but a main influencer is that for

each company, a typical area exists at a

given point of time on which to focus the

supply chain performance improvement

efforts.