- Value Chain Excellence

- Company Business Performance

- Supply Chain Performance

- Supply Chain Strategy

- Integrated business management (S&OP)

- Digital Transformation

- Operational Improvement

- Transparency

- Complexity

- Agility

- Responsiveness

- Customer Needs

- Delivery Reliability

- SC Segmentation

- Inventory optimization

- Throughput Times

- Order Management

- Planning Excellence

- Cost management

- Logistics Cost

- Working Capital Optimization

- Supplier Optimization

- Transport Optimization

- Network Optimization

- Post Merger Integration

AGILITY: KEY TO SURVIVAL IN A COMPLEX, VOLATILE WORLD

Source: Bölzing, D., Erfolgsfaktoren SCM - Agilität und Organisation, Logistik-Heute 11 + 12, 2015

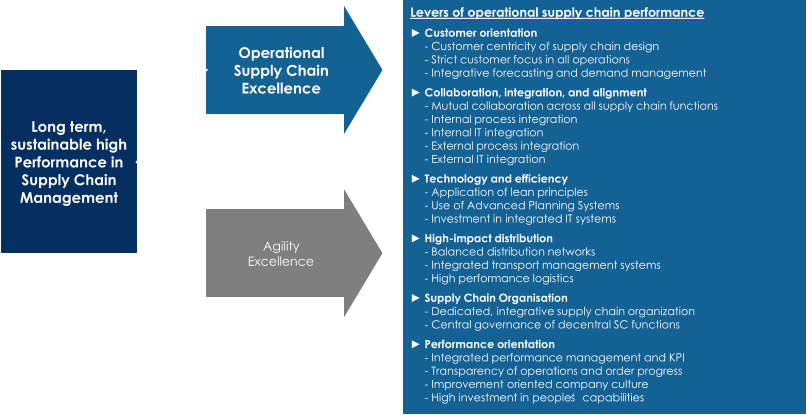

Leaders strive for operational excellence and agility excellence

Today’s volatile business world requires a different approach than the efficiency-

oriented decades of the past. Agility in the value chain, and in the supply chain,

has become a key requirement to cope with slow as well as sudden changes.

Typically, there are two types of agility:

•

On an overall organizational level, it addresses the capability of the

organization to adapt quickly to new general business challenges. Examples for

this are channel volume shifts, emergence of new business models, new types

of customer interaction, or major regional shifts.

•

On an operational level, it stands for the capability of the organization to adjust

the supply chain to shifts in demand, supply, and in its product portfolio. This

requires a specific kind of flexibility in production, distribution, and sourcing.

What we have seen in our market research is that successful companies who are

nimble and agile, always have already mastered the challenges of implementing

operational excellence in their operations. These techniques build the foundation

to have a fast, customer centric, cost-effective and high perfoming supply chain.

Operational supply chain

excellence is based on six

areas of using advanced

practices

Agility excellence in supply

chains is based on six areas

of using practices based on

early insights, and speed to

implement

Leaders build agility excellence into their organizations

In order to cope with the constant and ever increasing challenges from today’s

volatile business world, companies have started to establish mechanisms which

help them to have systematic insights into the nature of changes in their relevant

business environment. This requires a new focus on what is really important for the

company. Second main area to achieve is to systematically build enablers for fast

response to changes, and consequent adaptation into all areas of the

organization.

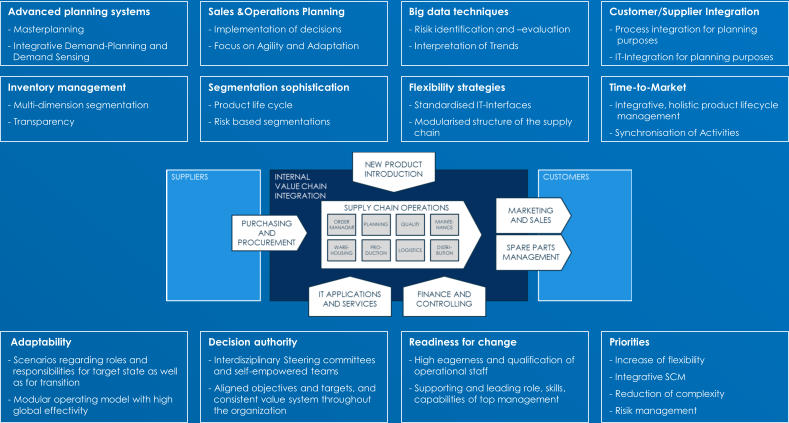

Leaders build key enablers for agility excellence into their operations

In our studies and observations, we have identified some key methods and

operational practices leading companies apply. These refer to a “hard tools

area”, but predominantly they are from a “soft foundation” of leadership

principles.

Enablers for agility excellence

in supply chains consist of

8 areas of integrative

methods and tools across the

company, and 4 leadership

and organizational practices

Source: EY SCM Study 2015;

EY Agility Study 2013

Source: EY SCM Study 2012, 2015