- Value Chain Excellence

- Company Business Performance

- Supply Chain Performance

- Supply Chain Strategy

- Integrated business management (S&OP)

- Digital Transformation

- Operational Improvement

- Transparency

- Complexity

- Agility

- Responsiveness

- Customer Needs

- Delivery Reliability

- SC Segmentation

- Inventory optimization

- Throughput Times

- Order Management

- Planning Excellence

- Cost management

- Logistics Cost

- Working Capital Optimization

- Supplier Optimization

- Transport Optimization

- Network Optimization

- Post Merger Integration

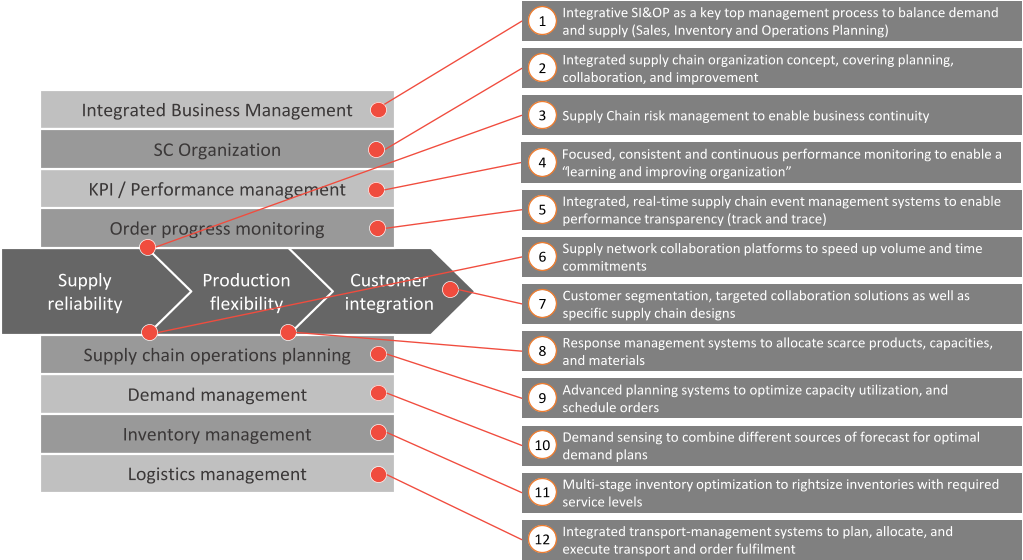

LEADING PRACTICES FOR ADVANCED SUPPLY CHAINS

Leading practices for advanced Supply Chain companies

•

Companies which operate in an advanced supply chain

mode have already realized a consistent, internally and

externally integrated supply chain. They act as an internal

chain, and also as an external chain element towards

suppliers, and towards customers.

•

In order to control their operations along the chain, they

are using a sophisticated set of IT enablers which provide

transparency, support decisions, and have automated

large parts of their planning.

•

As a result, they have smoothly running regular operations,

and therefore can focus their energy on the occasional

extraordinary situation - deviations in volumes, short term

customer orders, and short term disturbances on the

supply side.

•

All these sophisticated tools and enablers require a solid

foundation - in data integrity, transparency, controls,

speed, reliability, and flexibility of operations. Click here to

learn more about the foundations.

•

Please contact us if you want to learn more on how these

tools can improve your operations, and what the

preconditions are to operate these systems.