- Value Chain Excellence

- Company Business Performance

- Supply Chain Performance

- Supply Chain Strategy

- Integrated business management (S&OP)

- Digital Transformation

- Operational Improvement

- Transparency

- Complexity

- Agility

- Responsiveness

- Customer Needs

- Delivery Reliability

- SC Segmentation

- Inventory optimization

- Throughput Times

- Order Management

- Planning Excellence

- Cost management

- Logistics Cost

- Working Capital Optimization

- Supplier Optimization

- Transport Optimization

- Network Optimization

- Post Merger Integration

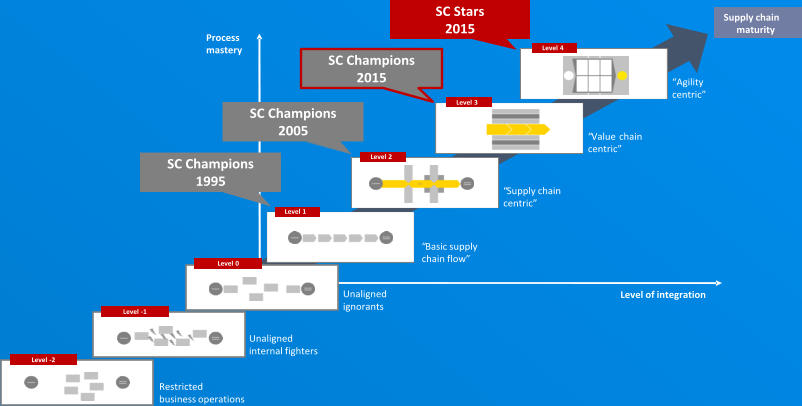

SUPPLY CHAIN MATURITY - KEY TO FIND THE RIGHT APPROACH WHICH FITS BEST TO

YOUR COMPANY, YOUR CURRENT NEEDS, AND YOUR FUTURE ASPIRATIONS

Supply Chain maturity can be

seen in two different levels:

•

Company view: How well is

“Supply Chain Thinking”

embedded in your company -

in processes, orgazionation,

leadership, investment priorities,

and attitude towards

customers, suppliers, and

service providers.

•

The visible implementation of

the “total flow” concept is key

to reach level 2 or higher. In

essence, the company is

structured around the supply

chain functions as the key

driver of revenue realisation.

•

Individual practices view: For

each of the functions in the

supply chain, and for key

supply chain practices, an

individual maturity exists.

•

A focused assessment shows

how well best practices are

established, in which areas

there is an improvement need,

and which areas can act as

leverage for higher

performance in the future,

using more advanced

practices in the supply chain.

Supply Chain Maturity Levels drive targeted, suitable solutions:

•

Before entering into individual “leading practices”, it is necessary to

determine the overall position and maturity of the company. All of the

“best practices” need particular pre-conditions to work properly, and

unfold their valuable contribution to supply chain delivery performance

•

A key insight over decades of using this assessment is that a company can

not jump a level: Each level needs to be established properly, with its own

mastery of this level’s practices. These form the foundation for the next level

of maturity. In particular, this addresses many areas, from processes, people

and their capabilities, IT systems, and use of particular tools and methods.

•

Each level shown here portrays a distinctly different level of internal

collaboration, and synchronization. Level 3 and 4 extend this perspective to

external collaboration. Level 2 is somewhat in between; it starts to practice

external collaboration and synchronization, but the internal capabilities are

not advanced enough to take full advantage of that. On that level, the

focus is still on mastering the internal challenges from executing customer

orders.

•

Level 3 and 4 are also levels, where supply chain principles drive how the

entire organization functions. On level 3, the supply chain itself is

embedded into clear tactical processes and tools (like SC operations

planning, inventory management, demand management, logistics

management), and also in a set of leadership instruments (like order

progress monitoring, performance management, SC organization, and

integrated business management using S&IOP).

•

Level 4 reflects a company concept which is acting in a more virtual

manner; going deeply into processes of customers and suppliers, but also

organizing its own operations based on the principle of “Best Capability

Leverage”. Service providers are managed to deliver best performance,

internal agility is key, and core competences are defined by “control over

supply chain performance”. An optimal cost position of often the result, but

not the real main driver for these companies.

•

Maturity levels 0 and lower indicate a lack of collaboration - each function

optimizes itself with best intentions, but there is no common set of targets

serving as a backbon for bundling and directing the internal energy.

Therefor every day a lot of lost energy is produced. On level “-1” internal

politics are more important than serving customers, and the own company.

Thus even more energy is destroyed for non-value adding purposes.

•

We have also seen level “-2” in economies who are just making their way to

western standards. When a purchase order is not a binding contract with

commitment to be fulfilled in the promised and confirmed way, or

inventory records follow other criteria than “goods entry”, our known supply

chain methods have no foundation to deliver any useful result. Therefore

these conditions need a very different approach.