- Value Chain Excellence

- Company Business Performance

- Supply Chain Performance

- Supply Chain Strategy

- Integrated business management (S&OP)

- Digital Transformation

- Operational Improvement

- Transparency

- Complexity

- Agility

- Responsiveness

- Customer Needs

- Delivery Reliability

- SC Segmentation

- Inventory optimization

- Throughput Times

- Order Management

- Planning Excellence

- Cost management

- Logistics Cost

- Working Capital Optimization

- Supplier Optimization

- Transport Optimization

- Network Optimization

- Post Merger Integration

ADVANCED SCM - REFERENCE MODEL FOR AMBITIOUS LEADERS

High performance in an Advanced Supply Chain

Environment

•

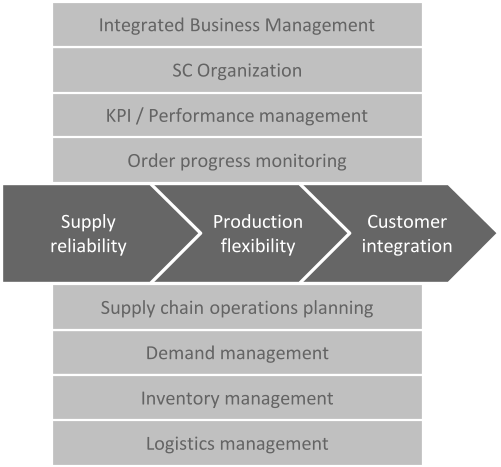

Today’s reference model for ambitious companies is the

advanced supply chain concept. It builds on the

foundations of supply chain centric organization, but adds

targeted management concepts, and important “process

worlds” to the supply chain centric organizational design.

•

Companies which operate in an advanced supply chain

mode have already realized a consistent, internally and

externally integrated supply chain. They act as an internal

chain, and also as an external chain element towards

suppliers, and towards customers. Therefore their internal

value chain focuses on three key dimensions to enable

their operations:

o

Production flexibility to adjust to changes in product

portfolio, customer demands, and volume variations.

o

Supply reliability to ensure continuity and predictability

of materials, goods, and services required to make the

products

o

Customer integration to continually improve the ways

of interaction with the market; this builds on joint

improvement initiatives as well as on a set of targeted

practices to focus on operational excellence,

predictability, and flexibility.

•

In their operations they use a set of tactical enablers,

processes, and ways of working. They have developed

advanced ways to plan their execution, to have deep

insights into their future market demands (and the

associated risks), but also to have balanced inventories.

Their logistics are designed and equipped to have high

efficiency, but also high flexibility, reliability, and

transparency using advanced transport management

systems.

•

To manage the supply chain’s performance and

execution processes, a set of organizational enablers is

established. As a foundation, systems support

transparency in operational status, but also deliver insights

regarding the current performance levels. A stringent set

of KPI is used to monitor the performance, and a task-

force oriented approach works on continuous but also

sporadic improvements. And the overall business balance

of demand, supply, and own operational development, is

managed by an integrated business planning - Sales and

Operations Planning as top management process to

manage the entire company.

•

As a result, they have smoothly running regular operations,

and therefore can focus their energy on the occasional

extraordinary situation - deviations in volumes, short term

customer orders, and short term disturbances on the

supply side.

•

All these sophisticated tools and enablers require a solid

foundation - in data integrity, transparency, controls,

speed, reliability, and flexibility of operations. Click here to

learn more about the leading practices used by these

companies.

•

Please contact us if you want to learn more on how this

model can be applied to your organization, and improve

your operational performance.